How To Stop Hydrolysis In Shoes

Hydrolysis, the aging of shoe soles explained

Hydrolysis and polyurethane explained

Many of our shoes take the soles attached to the uppers by a process where 2 materials are brought together in a mould, the resultant chemic reaction forms polyurethane (PU). the employ of polyurethane makes a lightweight flexible sole which is not only shock absorbent but also extremely hard wearing, that'south why polyurethane is ideal for shoes.

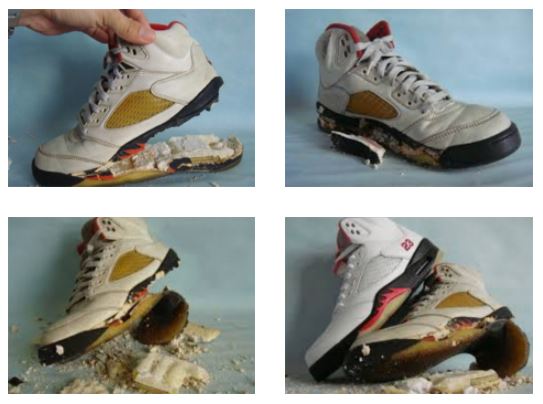

One of the main technical challenges with polyurethane is overcoming an ageing deterioration known every bit 'hydrolysis'. Hydrolysis is the chemical breakup of the PU polymer and the resulting physical breakdown or crumbling of the PU sole by the attack of water (usually in vapour form), occurring over a flow of several years (fifty-fifty when the shoes are in store!).

This procedure is accelerated by warmth and high humidity. Information technology will, therefore, happen more quickly in tropical climates, but besides in confined spaces (such as lockers) if the safety shoes are put away damp. In the nigh avant-garde country of hydrolysis, the PU sole will lose all its physical force, thus great or crumbling.

The Safety Jogger PU sole has been improved to increment the resistance against hydrolysis and performs better than any average safety shoe. Beneath yous will read why!

The attack of hydrolysis on a regular PU sole

Safety Jogger products with PU sole

WORKER S3

ORION S1P

ELEVATE S1P

BOTANIC S1P

The Safe Jogger PU sole

There are two types of PU soles. There is a Polyether based PU sole and a Polyester based PU sole. Polyether based PU soles have a high resistance confronting hydrolysis and low oil resistance. Polyester based PU soles have a low resistance confronting hydrolysis and high oil resistance.

Safety shoes are always using a polyester based PU sole. The bones PU sole used in most condom shoes on the market lasts for ane.v year in tropical conditions and 3 years in normal conditions.

The Safety Jogger PU sole, upgraded with improved resistance against hydrolysis, lasts for 4 years in tropical conditions and 8 years in normal conditions. Making our safety shoes a reliable product of endurance.

Do you have any questions nigh hydrolysis or aging shoe soles?

Don't hesitate to contact us right abroad, Nosotros're social!

You might also like to read

Safety features overview

A guideline to finding the perfect pair of rubber shoes for your work environment! This page is an overview of all the technical features nosotros have in our safety shoes.

Overview features

Electrical chance (EH) rated condom boots

Acquire more about electrocutions / electrical hazards & how nosotros forbid it in our safety shoes. Electrocutions are one of the most frequent hazards on construction sites. When in direct contact with ...

Electrical hazard

How-do-you-do-tech construction boots

It's not exactly a secret that yous no longer accept to exist a reckless railroad worker, with hands like sandpaper and a cigarette surgically attached to your bottom lip, to rock construction boots daily.

Construction boots

Grow YOUR Business organization & Get A DEALER

Safety Jogger is worldwide and always looking for people who trust our make as much every bit we do! Nosotros take a team of expert's ready for you to help with questions about our brand, technologies or reselling our products. So, don't hesitate to fill in this form, nosotros normally become back to you within a day!

Farther information?

Fill up in the course and we'll go in touch!

Source: https://www.safetyjogger.com/en/eu/technical/hydrolysis

0 Response to "How To Stop Hydrolysis In Shoes"

Post a Comment